Bucheon-si, Gyeonggi-do, South Korea – German premium automotive parts manufacturer MEYLE has announced a significant expansion of its electric vehicle (EV) component portfolio, aiming to produce over 4,000 types of electrification parts. This strategic move, revealed on June 20, underscores the company's commitment to addressing the burgeoning demands of EV repair and maintenance in the rapidly evolving e-mobility landscape.

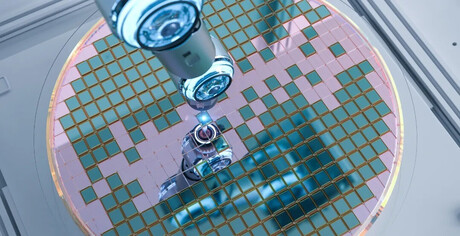

Since 2016, MEYLE has proactively developed core components and innovative solutions for electric and hybrid vehicles, anticipating the surge in demand. The latest announcement solidifies its dedication to meeting the challenges of the e-mobility era by vastly expanding its product offerings for the aftermarket. This comprehensive range will include high-quality products for hybrid and electric vehicles, emphasizing technical expertise gained from in-house development, testing, and production. MEYLE's product teams are consistently expanding this portfolio, which already features advanced components like optimized control arms, efficient filters, and robust suspension parts, often exceeding original equipment standards and backed by a four-year guarantee on MEYLE HD parts.

The transition to e-mobility is an undeniable global reality, particularly pronounced in Europe. The European Union, a vibrant EV market, has legislated a ban on the sale of new internal combustion engine (ICE) vehicles from 2035. This directive, passed by the European Parliament in 2023, mandates that all new light vehicles sold must be 100% free of CO2 emissions, effectively halting sales of gasoline and diesel cars, including most hybrids. While there have been ongoing discussions and some proposed exceptions for vehicles running exclusively on carbon-neutral e-fuels, the core objective of climate neutrality by 2050 remains firm. This regulatory push by the EU signifies a massive shift in the automotive landscape, making a robust EV aftermarket infrastructure critical.

In preparation for this transformative period, MEYLE collaborated with market research firm INNOFACT to conduct a comprehensive survey of 274 independent workshops in the DACH region (Germany, Austria, and Switzerland), where EV adoption is significant. The simulation results for 2035 paint a clear picture: while an estimated 135 million ICE vehicles will still be on European roads, over 80 million will be EVs, with more than 21 million of these being over eight years old. Projections suggest that EVs will constitute at least 30% of the entire vehicle fleet by 2035.

However, the survey also highlighted critical gaps in the current aftermarket. The majority of workshops are not yet fully equipped for comprehensive EV repair. Only one in five workshops is capable of handling all types of EV repairs, including crucial high-voltage system work. Despite 40% of respondents reporting weekly EV visits, a mere 3% of workshops derive over half of their revenue from EV servicing. While 47% anticipate their business shifting towards EV-centric operations within the next five years, only 16% have already invested in specialized EV training.

The identified solution for these challenges points strongly towards enhanced partnerships with parts companies. A significant 64% of respondents identified aftermarket parts companies as their most vital partners. Specific needs articulated by workshops include access to specialized parts and solutions (61.7%), technical training encompassing high-voltage systems (55.3%), and the provision of diagnostic tools and repair guides (48.9%). Furthermore, 65% of workshops emphasized the necessity of specialized EV training courses and certifications, while 60% called for online platforms offering technical support.

The situation in South Korea mirrors the European challenges. The country is projected to surpass 1 million cumulative EV registrations this year, with the government targeting 4.2 million EVs by 2030. As the warranty periods for many early-adopter EVs begin to expire, a substantial number of owners will seek private service centers. Yet, the current infrastructure for EV parts and specialized repair know-how remains in its infancy. Unlike ICE vehicles, EVs possess fundamentally different repair processes, and the presence of high-voltage batteries necessitates rigorous safety protocols to prevent serious incidents like fires. The quality of electrification components and established repair expertise will play a decisive role in ensuring the safe and reliable maintenance of out-of-warranty EVs.

To proactively address these critical needs, MEYLE's strategy extends beyond merely expanding its EV parts supply. The company is committed to fostering industry-academia collaboration to cultivate future generations of skilled repair technicians. Through its network of MEYLE service centers, the company aims to establish a reliable supply chain for EV-specific parts and disseminate crucial EV repair expertise, thereby ensuring that the aftermarket is well-prepared for the ongoing e-mobility revolution. This holistic approach reflects MEYLE's understanding that a successful e-mobility transition requires not only innovative parts but also a robust ecosystem of trained professionals and accessible support.

[Copyright (c) Global Economic Times. All Rights Reserved.]