Bukit Timah, Singapore – In the upscale residential enclave of Bukit Timah, Singapore, a house stands in stark contrast to its surrounding 1990s counterparts. Unlike the ornate and busy aesthetics of its neighbors, architect Lim Koon Park has taken a radical approach. This is 'QR3D,' Singapore's first fully 3D-printed house. Spanning 6,130 square feet over four levels and boasting seven bedrooms, this dwelling is more than just a technological demonstration; it serves as a showcase of innovation and a sanctuary.

"I wanted to create something more than just a technological demonstration," says Lim Koon Park. "Tech-driven architecture often results in generic efficiency or experimental forms lacking livability. We sought something more nuanced." Lim, founder of Park + Associates, has undertaken diverse projects, from family residential compounds to resort developments.

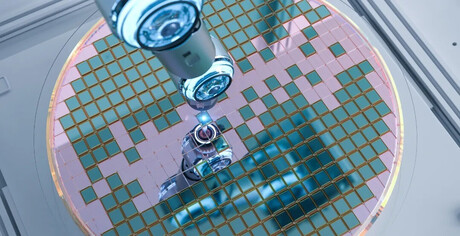

Innovative Construction Method: On-site and Off-site Printing

This two-year project came to fruition through a collaboration with CES_InnovFab, a local 3D concrete printing specialist. This period was significant, as Singapore's construction industry faced severe labor shortages and soaring costs in the post-pandemic era. Lim had long been interested in alternative construction methods and materials applicable to mainstream architecture. He approached this project similarly to a conventional residential design process, with modifications for the printing process applied later.

Specifically, construction was divided into two methods. Some walls were printed layer by layer on-site to avoid Singapore's tropical downpours. Other elements were formed in a factory environment before being transported to the site. This eliminated the need for the numerous workers typically involved in formwork installation, bricklaying, plastering, and painting on traditional construction sites.

Overcoming Technical Challenges: The Oculus and 'Printed Bricks'

To create the house's distinctive Oculus, a conical void soaring almost six meters high, the architectural team had to employ even more innovative methods. "We actually printed 'bricks' for the sloped sections," Lim explained. "The angle was a technical issue, as concrete tends to collapse when printed at certain slopes. Instead of waiting for a special fast-drying mix to be developed, we adapted by printing smaller components and assembling them."

The project demanded a steep learning curve but was equally rewarding. "This was our first time working with 3D printing technology," Lim recalled. "It required much more problem-solving and collaboration than conventional methods. Even basic elements like printing near walls with limited nozzle access had to be resolved on the fly. But that's what was most satisfying – we were finding solutions in real-time."

Efficiency and Sustainability: Overcoming Traditional Construction Drawbacks

Lim noted that traditional construction methods require numerous specialists, revealing the fatigue of someone who has overseen too much conventional building. However, the 3D printing process eliminated several stages required for a single wall. There was no need for timber formwork for concrete pouring, no bricks, and no unfinished walls. This approach resulted in reduced waste, labor costs, noise, construction traffic, and dust, benefits Lim believes could drive wider adoption of the technology.

Harmonizing Functionality and Aesthetics: The Role of the Oculus and Sustainable Design

The house's temperature control intuitively responds to Singapore's tropical climate without complex systems. The Oculus is more than just an architectural spectacle; it serves a practical purpose. It provides natural light while drawing hot air upwards, where passive turbo extractors expel it outdoors. This central void also carries emotional weight. "I'm fascinated by the dining space beneath the Oculus," Lim remarked. "It's dramatic during thunderstorms, contemplative at dusk, and reveals something new with every meal."

The house unfolds like a choreography, with each space connecting to the central void. Floor levels and spacing are adjusted to create feelings of compression and release. Ceiling heights vary from a cozy 9.5 feet in the indoor terrace to a liberating 16.5 feet in family gathering areas. Glimpses of the Oculus appear unexpectedly, helping to orient oneself within the concrete shell.

Sustainability is also evident in the material choices. Structural concrete works in conjunction with the printed elements. Flooring combines large format tiles, recycled composites, and engineered wood. The powder room floor reuses discarded marble scraps from a local stone supplier's waste stream.

Other environmental considerations are integrated into the design. The west facade acts as a party wall with the adjacent house, avoiding intense afternoon sun. Deep eaves shade the southeast-facing spaces, and minimal windows reduce heat gain in bedrooms. A heat pump water heater releases cool air as a byproduct into the top floor spaces, enhancing cooling efficiency.

Authenticity That Doesn't Hide Technology: Exposed Printed Surfaces

What is truly radical is Lim's unwillingness to hide the technology. The striated surface, where each printed concrete layer is visible like geological strata, is intentionally exposed, with no additional plastering or painting.

"Architecture has become obsessed with a perfectly polished finish," Lim said, running his hand along the ridged wall. "We are celebrating the process itself. You can literally read how this house was made."

Lim, who studied architecture at the National University of Singapore, the University of Sheffield in the UK, and UCL Bartlett School of Architecture, views QR3D as one step in a longer journey. Through this project, he wanted to prove several points: that 3D printing can be applied to mainstream architectural projects in an urban environment, that it can create high-quality, emotive spaces, and that despite being a new technology, it can result in a house that remains relevant for decades.

"The technology exists now. What's needed is education, awareness, and research and development to gain momentum in mainstream architecture," Lim states. His office continues to move in unexpected directions, from multi-family residential compounds in Singapore to an eco-resort nestled in Fiji's 'Sleeping Giant' mountain, and entertainment complexes in Saudi Arabia. With QR3D, he has created something unique: a concrete poem that is both a technological advancement and a reassuringly human creation, a celebration of innovation and memory, articulated in the language of 'home.'

[Copyright (c) Global Economic Times. All Rights Reserved.]