Hiperbaric, a Spanish high-pressure technology specialist headquartered in Burgos, announced on the 9th that it has signed a contract to supply a large Hot Isostatic Pressing (HIP) system to Plus Metal, a Taiwanese aerospace component manufacturer.

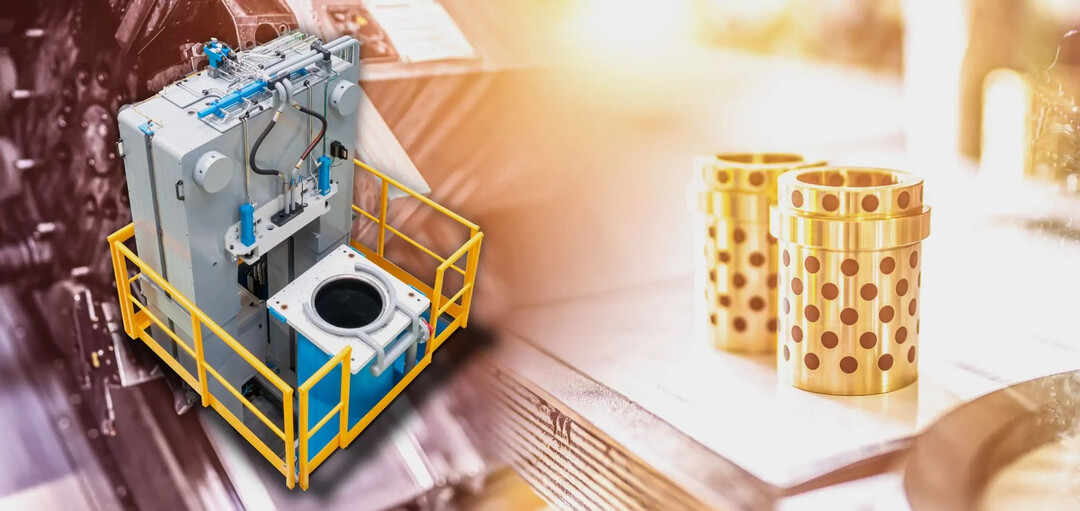

The Hiperbaric HIP 93 system, slated for installation at Plus Metal's headquarters in Taiwan, is among the largest in Hiperbaric's product portfolio. This investment is expected to significantly enhance Plus Metal's core capabilities in the high value-added aerospace component manufacturing sector.

Hot Isostatic Pressing technology is an essential process in advanced industries such as aerospace, playing a crucial role in improving the mechanical properties of components, increasing resistance to fatigue and thermal stress, and ensuring the structural reliability required in extreme operating conditions. HIP technology enables the manufacturing of complex-shaped parts by reducing internal defects and improving the surface finish of components produced through Powder Metallurgy and Additive Manufacturing methods.

Lin Zansheng, Chairman of Plus Metal, emphasized, "The introduction of HIP technology will solidify our company's position in advanced material applications and further strengthen Taiwan's crucial role in the international aerospace supply chain."

Andrés Hernando, CEO of Hiperbaric, highlighted his company's 25 years of accumulated experience in high-pressure technology innovation and its expertise in water-based high-pressure equipment reaching 6,000 bar (87,000 psi). He added, "This extensive experience has allowed us to develop modern HIP equipment characterized by enhanced performance and reduced operating costs."

Hiperbaric HIP systems feature a core technology: the wire-wound pressure vessel. This design not only offers a 'leak before break' safety feature, extending lifespan and preventing catastrophic failures, but also provides thermodynamic advantages. The coil-shaped construction allows cooling channels to be placed very close to the vessel wall, acting as a heat exchanger and enabling rapid cooling (Fast Cooling technology) within the equipment.

This contract is projected to significantly boost Plus Metal's competitiveness in the high value-added aerospace component market and positively impact the development of Taiwan's aerospace industry. Hiperbaric's advanced HIP technology is expected to serve as a crucial foundation for Plus Metal to produce more innovative and reliable aerospace components.

Key Terms:

Hot Isostatic Pressing (HIP) technology: A process that uniformly compresses metal or ceramic powders under high temperature and pressure to increase density and eliminate porosity. Components manufactured through this process exhibit excellent material properties such as high strength, durability, and reduced internal defects, making them widely used in high-performance industries like aerospace, automotive, and medical.

Plus Metal: An aerospace component manufacturer based in Taiwan, specializing in producing various high-quality components, including aircraft structural parts and engine components, based on precision machining technology and quality control systems.

Hiperbaric: A global leader in high-pressure technology headquartered in Spain, also possessing unique technological expertise in High Pressure Processing (HPP) equipment, a non-thermal pasteurization technology for the food industry. The company has recently been actively involved in the development and supply of HIP systems for metal processing.

Application of HIP technology in the aerospace industry: Aircraft engine turbine blades, aircraft structural components, and other parts must withstand extreme temperatures, pressures, and repetitive loads. Therefore, HIP technology is essential to minimize internal defects and densify the microstructure to enhance material properties. It also facilitates the manufacturing of complex-shaped parts, increasing design freedom and improving production efficiency.

[Copyright (c) Global Economic Times. All Rights Reserved.]