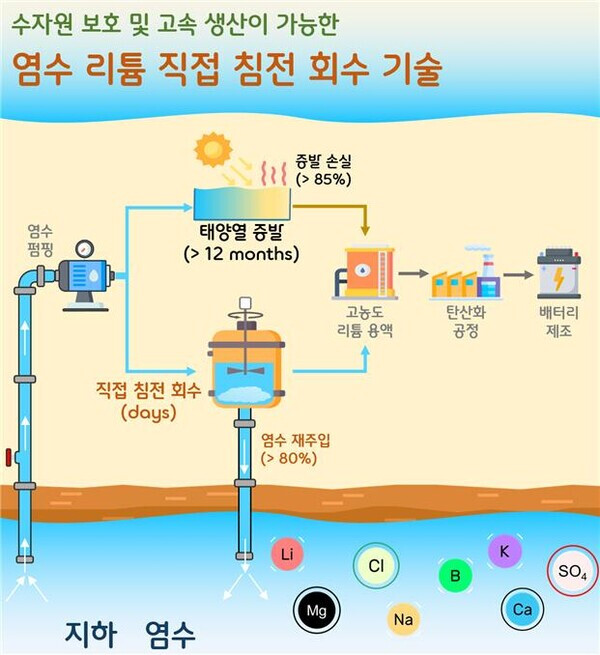

A research team led by Dr. Park In-soo at the Korea Institute of Geoscience and Mineral Resources (KIGAM) has developed a novel technology for rapid and efficient lithium extraction from low-grade brine. This technology is characterized by low production costs and high efficiency, and is expected to mark a significant turning point in the commercialization of brine lithium resources.

Traditional solar evaporation processes for lithium production have faced challenges such as low lithium recovery rates, long processing times, and water depletion. In particular, low-grade brine, with its low lithium concentration, has been difficult to utilize commercially. To address these issues, the research team introduced a low-temperature calcination and room-temperature water-leaching process, effectively separating and concentrating lithium from lithium precipitates.

The developed technology successfully produced 99.7% high-purity lithium carbonate powder through impurity purification and carbonation processes. Compared to conventional methods, this technology eliminates the need for time-consuming and costly pre-treatment and evaporation concentration processes. It can also be applied to various brines, including low-grade brine and industrial wastewater, offering significant advantages.

Dr. Park In-soo stated, "This research presents a new method for rapid and efficient lithium extraction from low-grade brine, marking a significant milestone in opening the future of the lithium industry. We will contribute to strengthening our competitiveness in the global lithium market through continuous efforts for technology commercialization and international research collaboration."

The research findings were published in the international journal "Chemical Engineering Journal," receiving international recognition for their excellence.

[Copyright (c) Global Economic Times. All Rights Reserved.]