According to a Reportasia report, lithium producer Lithium Argentina AG and Chinese lithium giant Ganfeng Lithium Co. Ltd. have taken steps to pursue a large-scale lithium production project by signing a Memorandum of Understanding (MOU) for the integrated development of the Lithium Triangle in Salta Province, Argentina.

This agreement aims to maximize operational efficiency by integrating three major lithium brine projects within Salta Province: Pozuelos-Pastos Grandes, Pastos Grandes, and Sal de la Puna. The goal is to secure a maximum annual production capacity of 150,000 tons of lithium carbonate. This is interpreted as a strategic move to actively respond to the rapidly increasing lithium demand from the battery and electric vehicle industries.

Looking at the equity structure of each project, Ganfeng Lithium holds 100% of the Pozuelos-Pastos Grandes project. In the Pastos Grandes project, Lithium Argentina holds 85% and Ganfeng Lithium holds 15% of the shares, respectively. For the Sal de la Puna project, Lithium Argentina has secured 65% and Ganfeng Lithium 35% of the equity. The two companies plan to build an optimal cooperation model considering the characteristics and strengths of each project.

Sam Pigott, President and Chief Executive Officer (CEO) of Lithium Argentina, stated, "We have already accumulated successful cooperation experience with Ganfeng Lithium through the operation of the Cauchari-Olaroz brine lake." He added, "Through this integrated development, we aim to significantly increase lithium production in the Salta region and contribute to making Argentina a leader in the global lithium industry."

◇ Introduction of Environmentally Friendly Production Methods and Review of Lithium Chloride Production Potential

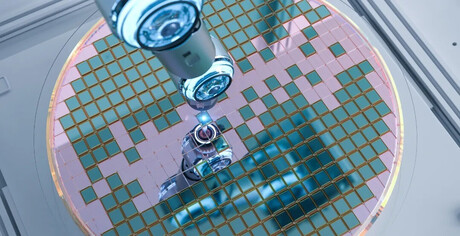

A key feature of this integrated development plan is the strong commitment to establishing an environmentally friendly production system. The two companies plan to gradually introduce innovative Direct Lithium Extraction (DLE) technology alongside the traditional solar evaporation method. Compared to the conventional method, DLE technology significantly reduces water usage, lowers the consumption of chemical reactants, decreases operating costs, and minimizes environmental impact.

Currently, the two companies are jointly constructing a pilot DLE technology plant with an annual capacity of 5,000 tons, which will be installed at their existing joint venture site in Cauchari-Olaroz. Expected to be completed this year, this pilot plant will allow them to verify the economic and environmental benefits of the new technology in a real operating environment.

Furthermore, the two companies are comprehensively reviewing the potential for producing lithium chloride in addition to lithium carbonate. This is expected to build a foundation for more flexibly responding to the specific needs of various battery manufacturers in the future. Given the continuous increase in lithium demand from the battery industry due to the rapid growth of the electric vehicle market, this integrated development is expected to play a crucial role in securing a stable lithium supply chain.

◇ Pursuing Joint Funding and Long-Term Supply Agreements

To ensure the successful implementation of the project, the two companies are actively exploring joint funding options. This includes pursuing long-term supply agreements (Offtake Agreements) and remaining open to the participation of strategic investment partners or major customers, discussing various cooperation plans.

The success of this large-scale joint venture is contingent upon the fulfillment of customary conditions, including the signing of a final agreement, approval of relevant development plans, and regulatory approvals. However, with the strong cooperation will and technical expertise of Lithium Argentina and Ganfeng Lithium, attention is focused on whether they can open a new chapter in Argentina's lithium industry.

[Copyright (c) Global Economic Times. All Rights Reserved.]