The advent of the electric vehicle (EV) era is fundamentally transforming the automotive industry. The roar of the internal combustion engine and the smell of fuel that captivated drivers for decades are fading into history, as electric power takes hold of everything from popular sedans to luxury SUVs and pickup trucks. Amidst this massive wave of transition, a lightweight, overwhelmingly efficient 'heart' is expected to redefine the future of electric vehicles.

The Emergence of Ultralight, Ultra-High Efficiency Motors

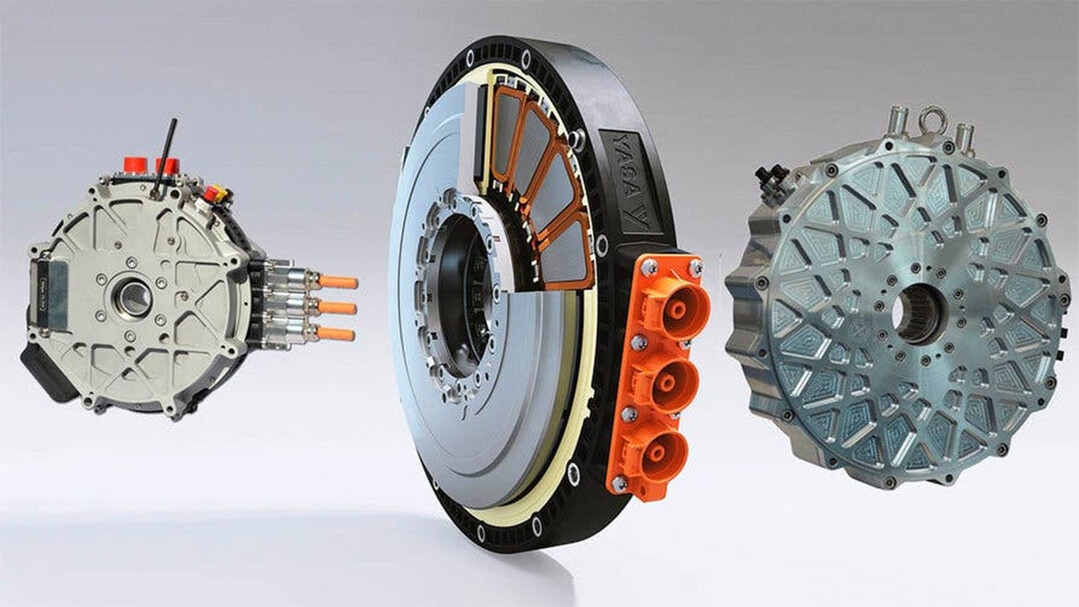

YASA, a UK-based subsidiary of Mercedes-Benz, has recently captivated the EV industry with the unveiling of a revolutionary prototype motor. It's an Axial Flux motor weighing just 13.1 kg and delivering a maximum power output of 550 kW (approximately 747 horsepower).

The power density achieved by this motor, at 42 kW/kg, is an unofficial world record, nearly doubling the industry standard of 23 kW/kg previously held by Helix's motor. Considering that the power density of typical automotive electric motors is around 5-15 kW/kg, YASA's achievement is regarded as a radical technological innovation, surpassing even the motor densities found in the aerospace sector. The fact that this 13 kg piece of equipment generates more power than a typical Hellcat engine clearly demonstrates the technology's potential.

The Potential of Axial Flux Technology and Production Feasibility

The core of the YASA motor lies in its adoption of a thin, flat, disc-shaped Axial Flux design, rather than the Radial Flux method typically used in existing EVs. This design inherently offers higher torque density and efficiency, playing a decisive role in the motor's miniaturization and weight reduction.

Tim Woolmer, YASA's Chief Technology Officer (CTO), emphasized that the motor's design does not rely on rare or expensive materials and that it can be mass-produced at an annual volume of 10,000 to 50,000 units. This suggests that the technology is not confined to the lab but can be applied to high-performance EVs at a reasonable manufacturing cost. Furthermore, it promises excellent cooling performance, maintaining near-rated output using standard cooling fluid and capable of sustaining maximum output for about five seconds.

A Shift in EV Design Paradigms

While advances in battery technology are certainly crucial to the growth of EVs, motor efficiency and power density also play a critical role in vehicle performance and design. A motor this powerful, yet small and light, has the potential to change the EV design paradigm.

Performance Enhancement: Explosive power required for high-performance sports cars can be achieved with fewer motors.

Weight Reduction and Space Optimization: Reducing the motor's weight and size lowers the vehicle's overall mass and frees up space for the battery or the passenger compartment, thereby improving driving range and practicality. This is particularly expected to make a revolutionary contribution to the design of high-performance sports cars where space is at a premium.

YASA’s motor technology is anticipated to be first deployed in Mercedes-AMG's next-generation high-performance vehicles. Mercedes-AMG has already showcased YASA’s axial flux motor in the prototype AMG GT XX and is preparing to use this technology as the core powertrain for upcoming production models. Mercedes-Benz secured this key technology by acquiring YASA in 2021 and aims to mass-produce EVs incorporating the axial flux motor around 2025.

This technological leap in the drive motor sector, alongside battery innovation, will be a critical turning point that elevates the potential of electric vehicles. The 13 kg motor is making the future of EVs lighter and more powerful with unprecedented efficiency and performance.

[Copyright (c) Global Economic Times. All Rights Reserved.]