Amidst the anticipated widespread shift toward electric and hydrogen vehicles, Mahle, a German automotive components company, is drawing attention by unveiling a future internal combustion engine that defies existing expectations. This engine uses pure ethanol (E100) as its fuel instead of gasoline or diesel, presenting a practical, decarbonizing alternative to fossil fuels.

Why the Ethanol Internal Combustion Engine is a Future Alternative

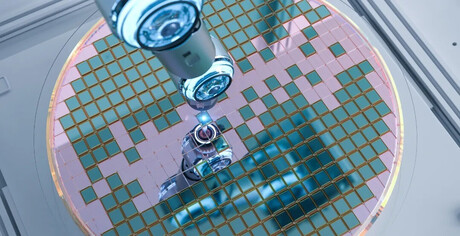

At the IAA Mobility event in Munich, Germany, Mahle introduced the 'Powercell Unit,' a set of internal combustion engine components designed to operate on pure ethanol (E100). This technology is highly significant as a transitional or parallel solution, especially as the pace of electric vehicle adoption is slower than anticipated and the decarbonization of the global vehicle fleet is urgent.

Ethanol is a biofuel produced through the fermentation of plant-based biomass, such as sugarcane or corn. According to a Life Cycle Analysis, using sustainably produced bioethanol (E100) can reduce carbon dioxide emissions by up to 70% compared to conventional fossil fuels, making near-carbon-neutral operation possible. This can be explained by the concept of the Carbon Cycle, where the plants used to produce ethanol absorb CO2 during growth, meaning the carbon emitted during combustion is not newly added to the atmosphere.

Mahle's Technological Innovation: An Ethanol-Optimized Engine

Mahle's Powercell Unit consists of pistons, piston pins, piston rings, and valve train components that are optimized for the specific characteristics of pure ethanol.

Optimized Components: Ethanol is more corrosive than gasoline and is likely to increase engine wear due to the formation of formic acid and a large amount of water during combustion. Considering these properties of ethanol, Mahle developed special components with enhanced resistance to corrosion, wear, and thermal stress.

Increased System Efficiency: This innovative system ensures minimal lubricating oil consumption and provides the additional benefit of reducing fuel consumption by up to 1.5%. This is part of Mahle's 'Efficiency' strategy, which aims to boost the energy efficiency of propulsion systems and accelerate decarbonization.

Immediate Applicability: One of the greatest advantages of this technology is its immediate applicability to existing vehicles. It allows for a rapid increase in the use of renewable fuels in currently operating vehicles without sacrificing performance or reliability, thereby advancing the decarbonization of the transport sector. This reflects Mahle's strategic stance on Technological Neutrality—the ability to address environmental issues without costly infrastructure changes.

The Practical Barriers and Future of Ethanol Fuel

Ethanol fuel possesses technical advantages, such as a high-octane rating, which reduces engine knocking and allows for a higher compression ratio, thus improving thermal efficiency. Furthermore, it emits less air pollutants, such as carbon monoxide, during combustion compared to gasoline.

However, ethanol also has disadvantages. Its lower energy density per unit volume compared to gasoline means it consumes more fuel for the same driving range, resulting in lower fuel economy. In addition, ethanol is highly hygroscopic, meaning it absorbs moisture from the air, which can cause corrosion in fuel lines or metal tanks, particularly in older vehicles or those with components not designed for alcohol durability.

While ethanol is already mainstream in some countries like Brazil, global expansion requires the establishment of a sustainable biomass supply chain and securing the durability of ethanol-only or flex-fuel vehicles. Mahle's technology is praised for compensating for ethanol's drawbacks and maximizing its advantages, opening up new possibilities for the internal combustion engine in a future mobility landscape that has been overly focused on electric and hydrogen vehicles.

[Copyright (c) Global Economic Times. All Rights Reserved.]